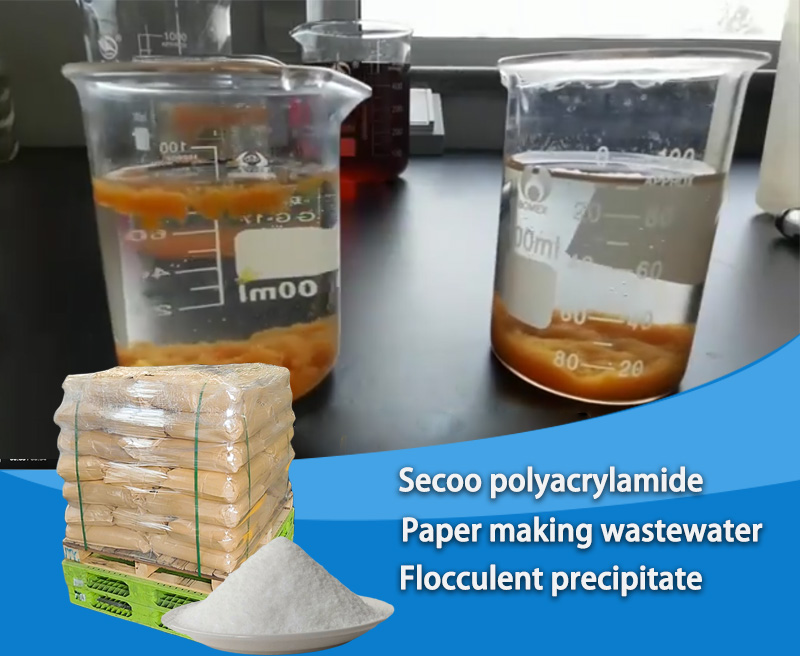

Polyacrylamide(PAM) is a critical chemical agent in treating paper mill wastewater. Its proper selection and application are paramount for efficient operations, compliance with environmental regulations, and cost control.

1. The Role of PAM in Paper Mill Wastewater Treatment

PAM polymer solubilis aquae est qui primum per duos mechanismos functionat:

Coagulation (Charge Neutralization): prima pro cationic PAM. Charges positivas eius negativas superficies (Zeta potentiales) particularum colloidorum (e.g. fibres, impletores, moribus) neutraliserunt, destabilizantes et permittit illis aggregare.

Flocculatio (Bridging): catena polymera longa PAM adsorbunt super superficies particularum destabilisarum et conponunt illos simul, formantes magnas, densas et celebrantes flores.

Omnia effecta sunt:

Enhanced Solid-Liquid Separation: Fast formation of settleable or floatable flocks in clarification processes (sedimentation or flotation).

Qualitate aquae improveta: significanta reductione Solidis Suspendentis (SS), Demand Oxygeni Chemicalis (COD), color, and turbidity of the treated water.

Superior Sludge Dewatering: Condition sludge by binding fine particles, release bound water, and increasing the solid content of the dewated cake, reducing the disposition volume and cost.

2. Selection of Polyacrylamide (PAM)

Selection is a complex process that must be determined by laboratory jar tests and on-site trials, since wastewater composition varies greatly between mills. PAM secundum Ionium cargam categorizatur:

A. Selection by Ionic Type and Application Stage

Prosessus gradusWastewater/Sludge CharacteristicsMensa PAM recommendataRationale

Primary Treatment (Clarification: Sedimentation/Flotation)Neutral/alkaline pH, alta load of negative charged fibers, fillers (kaolin, CaCO) ₃), Et colloides. High SS and COD.Anionic (APAM) aut non-Ionic (NPAM)Anionic PAM synergistically works with inorganic coagulants (e.g., PAC, alum). The coagulant neutralizes charges; APAM ergo pont particulas destabilisas in flores magnos. NPAM est effectus in terminis pH neutral is.

Sludge Dewatering (Belt Press, Centrifuge)Sludge from biological treatment or primary clarification. Satura organica alta, carga negativa, hydrophila et difficile deaquae.Cationic (CPAM)Charges positivas CPAM negativas particibus organorum particibus negativas neutraliserunt. This, combined with polymer bridging, destroys the stable colloid structure, releasing water and improving dewaterability.

Dissolved Air Flotation (DAF)Habitur materia lucra sicut fines, resinas, et agentes.Anionic (APAM) or Low Ionicity CationicFormitur flores fortes stabiles magnitudinis rectae et densitatis efficantibus attachationibus microaeris et flotacionis rapidis.

B. Selection by Molecular Weight (MW)

Very High MW (>18 million g/mol): Ideal for clarification. Long polymer chains provide excellent bridging, forming large, fast-setting flores.

Medium to High MW (10 - 18 million g/mol): The most common range for sludge dewatering. Balances bridging ability with solution viscosity and handling.

C. Selection by Ionicity (For Cationic PAM - Critical for Dewatering)

Ionicita (densitate cargae) in percentage exprimetur et est clave parametro ad seleccionem cationic PAM in deaquationem pulchritudinis.

Low Ionicity (10-30%): Best for inorganic sludges (e.g., from primary treatment with lime or clay). These sludges require more bridging than charge neutralization.

Medium Ionicitatem (40-60%): Maximum versatilem. Suitable for mixed sludges (a mixture of primary and biological sludge).

High Ionicity (>60%): Essential for organic, biological sludges. These sludges have a high negative charge density and require strong charge neutralization to break down stable, water-holding colloids.

Note: Higher ionicity is not always better. Excess charge can cause polymer chain coiling, reducing its bridging efficiency and increasing cost.

3. Evaluating and Optimizing Effectiveness

Post praeceptam seleccionem, exercitus probabitur et optimizabitur.

Jar Testing:

Dosage optima determina: tempta diversas dozas PAM sub conditionibus stirrionis controllis. Observe magnitudinem formationis florum, velocitatem et claritatem supernatantis. Find the dose that gives the best performance at the lowest cost.

Optimize Mixing: Fast mix (for initial dispersion) and slow mix (for floc growth without shearing) are both critical.

Pilot/Field Trials:

Conduct e probas super instrumentum actum (ex. cineres press). Monitor key performance indicators: libus dryness, polymer consumption rate, clarity of centrate/filtrate, and processing throughput.

Indicatores clave exercitus (KPI):

Clarificatio: Acceleratione, turbiditate supernatantia/SS, removo COD.

Dewatering: Coke Solids Content (%), capture rate, filtrate claritatem, et dosage per tonnas solidorum aridi.

4. Considerations importantia

Dissolution: Aqua munda in cubiculo temperatura parata est (< 60°C). Use an automated mixing and aging system to ensure complete dissolution (typically 40-60 minutes) at a concentration of 0.1%-0.3%. Incomplete dissolution creates "fish eyes," reduces efficacy, and can clog equipment.

deposita: pulvere frigus in loco frigus, arida in vasis signatus, ut non absorberet humilitatem et libum. Solutione parata est vita limitata (normale <24 horas) quam catena polymer a degradat, reducit viscositatem et effectivitatem.

Punctus Additionis: Punctus injectionis optimum connexionem et mixendum cum pulvere aut wastewater debet.

pH: Wastewater pH can affect the charge density and performance of PAM. The pH adjustment may be necessary before polymer addition.

iCalImp

Non est PAM universal is ad molam litterarum litterarum wastewater.

Praeceptum aureum: Clarificatio usus Anionic PAM utilit; Sludge Dewatering primarily uses Cationic PAM.

Key Method: Selection must be based on jar testing and field trials to find the optimal ionic type, molecular weight, and ionicity for the specific wastewater and sludge stream.

Ultimate Goal: To achieve the best treatment efficiency (clear water, dry cake) at the lowest operating cost.

Collaborating with knowledgeable PAM suppliers who can provide technical support and sample testing is highly recommended for optimal results.

Si volueritis ad produktos nostros aut habere quaestiones, implete formam inferiorem, quaeso. We will contact you immediately after receiving it. Thank you for your choice.