Polyacrylamide (PAM) is a water-soluble linear polymer and is the most critical and widely used flocculant and settling agent in mineral processing wastewater treatment, often regarded as an indispensable "universal aid." Correct selection is paramount, as it directly determines treatment efficiency, operational costs, and the performance of downstream processes.

I. Role and Effectiveness of PAM in Mineral Processing Wastewater

Mineral processing wastewater is typically characterized by: large volume, high suspended solids (SS) content, presence of heavy metal ions and residual reagents, complex composition, and variable pH. PAM primarily performs the following functions to achieve water reuse or compliance discharge standards:

Flocculatio et Sedimentatio:

Mechanism: Active groups on the PAM molecular chain function through charge neutralization and bridging sweep flocculation. They adsorb on fine suspended particles and mineral fines, forming large, dense flocks ("pin flakes"), drastically accelerating their settling rate.

Effect: Significantly improves the efficiency of thickeners and clarifiers, producing clear supernatant and markedly reducing suspended solids content. Hoc functionem cordis eius est.

Slurry Thickening:

Mechanisms: In thicknesses, PAM promot aggregationem particiorum fine, relevantem aquam inter eos traxit ut densiorem subfluctum formaret.

Efectus: Increases the rate of water recovery and reuse, reduces fresh water consumption, and facilitates tailings disposition (e.g. dry stacking).

Filtrae assistentia:

Mechanismo: Flores formatae magnae et robusti sunt, resistentes fracturam. During filtration, they create a porous filter cake, reducing cake moisture content and increasing filtration rate.

Effect: Enhanced the efficiency of filters (e.g. filters presses, cinctures filters), reducing energy consumption and cycle times.

Removing of Heavy Metals and Contaminants:

Mechanism: Through adsorption and co-precipitation, PAM can help remove heavy metal ions (present as hydroxides or complexes) by entrapping them within the floc structure.

Overall Effectiveness: Using the appropriate PAM can typically reduce wastewater suspended solids from thousands of mg/L to below 150 mg/L (for discharge), and even to below 30 mg/L (for reuse). Clarification rates can be improved by several times to tens of times.

II. Key to Success: Correct Selection

Non est "universal" PAM. Selection must be site-specific and wastewater-specific. Testum laboratorium obligatorium est.

1. Understanding PAM Types

Classificata Ionica charge, PAM quattuor principes habet:

Cationic Polyacrylamide (CPAM): Melior pro dives organicos, colloidis negativi cargatis. Less common for primary sedimentation in mineral processing; Vix frequenter used for subsequent sludge dewatering.

Anionic Polyacrylamide (APAM): The most commonly used type in mineral processing. Idealis aquae neutral e aut alkaline ad particulas inorganicas positivo charged flocculare (ex. oxides metallos, slimes silicae).

Polyacrylamide non-Ionicus (NPAM): Conditionibus acidis aut neutralibus, ubi carga superficie particularum infirma est. Less affected by pH in saline environments but has slower dissolution.

Amphoteric Polyacrylamide (AMPAM): Utus est pro multo complexo variabile wastewater pH. More expensive and less common in mineral processing.

2. Core Selection Procedure

Step 1: Analysis qualitatis aquae (The Foundation)

Valor pH: ductus primus tipi ionici.

pH < 7 (Acidic): Prioritize non-Ionic (NPAM) aut Cationic (CPAM).

pH 7-14 (Neutral-Alkaline): Anionic (APAM) saepe optima est.

Suspendit Solids (SS) Concentration & Compositio: Mineralogia (ferrum, coper, phosphate, ore plumbo cinc) carga superficie particularum dicit.

Potentiale Zeta: Measurat superficiem particularum. Potentia maxima negativa est alta carga densitate CPAM ad neutralizationem requirit; A positive potential requires APAM. Hoc est unus ex optimis criteriis electionis scientiae.

Residual Reagents: Collectors, depressants, etc., can alter the surface properties of particles, affecting PAM performance.

Step 2: Laboratory Jar Testing (MANDATORY)

Hoc optimum produtu et dosage scrutare est.

Exemplo Preparatio: Collect representative wastewater samples.

Solution Preparation: Prepare 0.1% solutions of different PAM products (freshly prepared, use within 24-48 hours).

Testum stirring:

Adde a measured dose of PAM solution under rapid stirring (200-300 rpm) for 1-2 minutes for initial mixing.

Reduce a lente stirring (50-60 rpm) 5-10 minutis ut flocco formationem observare (granditudo, densitate et rate).

Observatio: cessa turbare. Observa velocitatem, claritatem supernatantis, et compactum seditionis.

Evaluatio: Measure turbidity aut SS of the supernatant. Compare the effectiveness of different types and dosages. Objectus est invenire produktum quod desiderat claritatem in minimo dosage.

Step 3: Teste Pilot-Scale

After successful jar tests, conduct on-site pilot trials to simulate real conditions (flow rates, mixing energy) to confirm results and fine-tune operational parameters.

3. General Selection Guide (Reference Table)

Tipo OreTypical Waste CharacteristicsTypa PAM preferataNotes

Iron OreParticula Neutral-Alkaline negativa chargedMedium-High Hydrolysis Anionic (APAM)Common, fast settling, large flocks

Copper/Lead-Zinc OreSaepe acidus saturat sulfurum & Metali graviNon-Ionic (NPAM) or Low Hydrolysis Anionic (APAM)Dependet on specific pH and Zeta Potential

Ore auro (Cyanidation)Alkaline, cyanides continetAnionic (APAM)

Rock PhosphateAcidicNon-Ionic (NPAM)

Coal/Coal WasheryNeutral, flumina carbonis continetMedium-Low Hydrolysis Anionic (APAM)Non-Ionic aliquando usatur

Sludge DewateringA clarificibus subfluctusMedium-High Cationic (CPAM)Utus ad pulserum filter/centrifuges

Note: This table is a general guide only. Testa laboratoria est essential.

III. Key Application Considerations

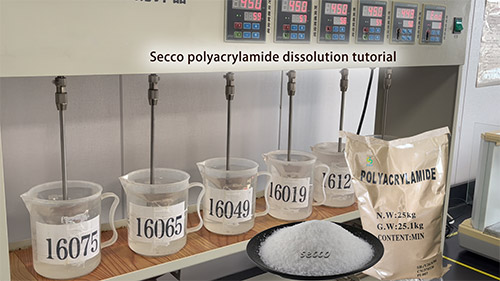

Dissolution and Preparation: PAM must be fully dissolved ("aged") to activate. Use dedicated mixing tanks and follow the "** sprinkle slowly into the vortex**" rule to avoid clumps ("fish eyes"). Agitatio sufficit ad mixendum sed non tantum violentiam ut degradaret catenas polymeros tondere.

Dosage: Plus non melior est. Overdosing can cause restabilisation of colloids, making the water cloudy again, reducing efficiency and increasing costs. The optimal dosage, typically between 1-10 ppm (g/ton of water), is determined by jar testing.

Moleculus Weight: Priorer molecular weight provides stronger bridging and larger flocs but dissolves slower and is more susceptible to shear degradation. Medium to high molecular weight (12-18 million) PAM is commonly used.

Adjustione regionis: Qualitate aquae fluctuat. Continuum monitorintem et minorem adjustationibus ad punctum dosationis et quantum necessarium est.

iCalImp

Efficientia: PAM valde efficiens est et est cordis tecnologia ad sedimentationem efficientem, reusationem aquae, et compliantiam in processione mineral is.

Selection: Is a systematic, scientific process. "Test first" est praeceptum aureum.

Analyze aquam qualitatem (especially pH and Zeta Potential).

Typus Ionicus et produktus specific via jar testing.

Conduce pilotum probos ut parametros finalisare.

Key to Success: Collaborate with technically capable suppliers who can provide a range of samples and technical support to conduct these tests, ensuring you achieve optimal treatment results at the lowest possible cost.

Si volueritis ad produktos nostros aut habere quaestiones, implete formam inferiorem, quaeso. We will contact you immediately after receiving it. Thank you for your choice.