Polyacrylamide a Henan Saceco producitus est prima in diversis laborationibus wastewater. Postulat effectum flocculationis et sedimentationis pigrorum, sed etiam ad deuriendum pigrorum ad faciendum siccationem pigrorum. Hodie, introducamus quas typos machinarum dewatering polyacrylamide applicatur!

Post desertum aquam sedimentationem tractat, multa pigra producetur. Even after concentration and digestion treatment, the moisture content still reaches 96%, and the volume is very large, making it difficult to be disposed of. Parabola dewateris ut cresceret saturatem libi pigri ut dimitteret occupatum regionem pilae pigri.

Most large and medium-sized wastewater treatment plants adopt mechanical dewatering. There are many types of dewatering machines, and according to the dewatering principle, they can be classified into vacuum filtration dewatering, pressure filtration dewatering, and centrifugal dewatering. This article will explain the working principle, structure, advantages and disadvantages of the commonly selected pressure filter (including belt pressure filter and plate and frame pressure filter), centrifugal dewatering machine and spiral stack sludge dewatering machine in domestic wastewater treatment plants.

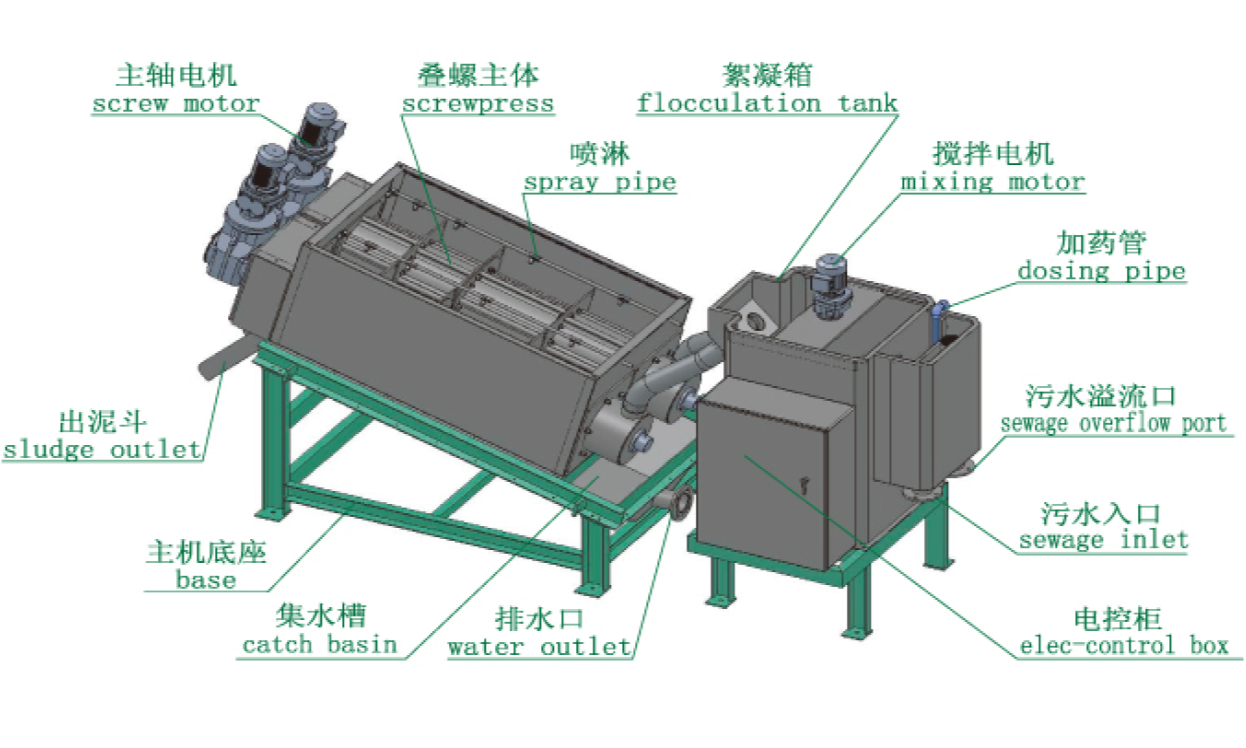

1. Spiral Stacked Sludge Dewatering Machine

1. Working Principle

(1) Concentration: When the spiral driving shaft rotates, the multiple solid-liquid contact plates located around the driving shaft move relative to each other. Under the action of gravity, water flows out through the gaps between the moving contact plates, reaching rapid concentration.

(2) Dewatering: Postquam pignus concentratus movetur in rotacio ventilae spiralae, fluctus spiralae graduale declinet secundum directum pugnus et inter anulos graduale angusta est. Volum speluncis speluncis semper diminuit. Under the action of the back-pressure plate at the outlet, the internal pressure gradually increases. In successive continuous rotation and pushing by the spiral driving shaft, the water in the sludge is squeezed out, and the solid content of the filter cake continuously increases, ultimately aching continuous dewater of the sludge.

(3) Selfmundatio: Rotatio spiralins fertur anulum moventem continuo rotare. The equipment achieves a continuous self-cleaning process by relying on the movement between the fixed ring and the moving ring, thus ingeniously avoiding the common clogging problem of traditional dewatering machines.

2. Structure

Machina dewatering a spirala ex corpore spirali, apparatus driving, tanki filtrati, systema mixtionis, frama etc. When the spiral sludge dewatering machine is working, it lifts the sludge to the mixing tank through a sludge pump. At this time, the dosing pump also quantitatively delivers the liquid to the mixing tank. Motor turbans totam systemam turbantem perducit ut pulverem cum liquido mixeret, per quam flores generat. Quando nivel liquidi supra limitam sensoris liquidi attinget, sensor accipit signum, causans principem corporis motorem spiralae functionem, sic proceduram deaquationis incipiens et permittit pulverem fluere in principem corporis spiralae. Sub actionem ventilae pignus graduum elevatur ad pulverem Fluit filtratus per interitum inter anulum fixum et anulum moventem.

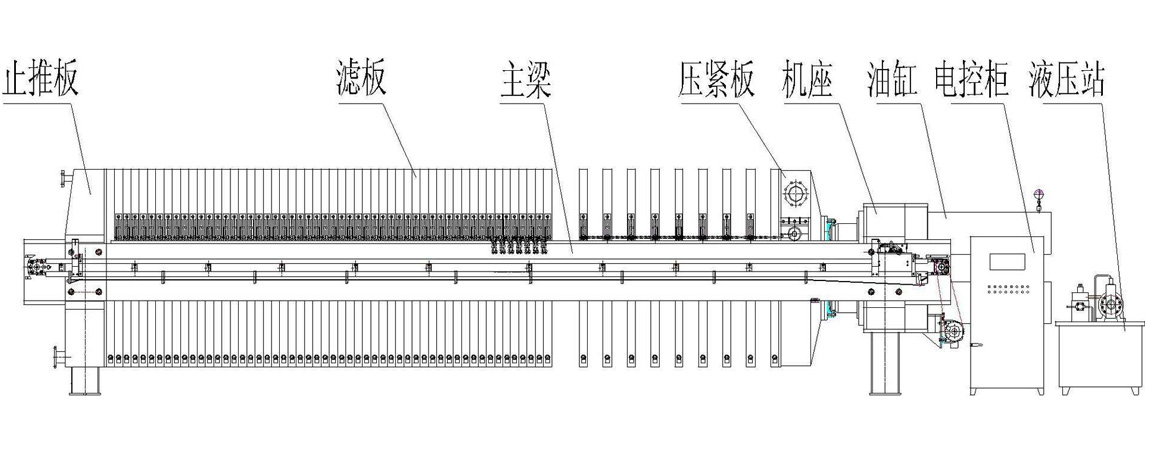

II. Plate and Frame Filter Press

1. Principle

Filtros fractarum ex alternationibus platearum et filter boxarum constituit, formantes castra filtrarum. Superficie platearum habet gemmas, et partes claudicatores sunt ut sustinerent pallium filtrum. The edges and corners of the filter boxes and plates have through holes, which, when assembled, form a complete channel that can introduce the suspension, washing water and discharge the filtrate. In utraque parte platearum et cisternae quae super trabem transversae sunt et plateae et cisternae simul pulsantur ab instrumento pressionis. The filter cloth between the plates and boxes serves as a sealing gasket. The feed pump pumps the suspension into the filter chamber, forming the residue of filter on the filter cloth until the filter chamber is filled. Filtra transierit per pallium filtram et fluit per pallium filtrae ad canales angulorum anguli platearum et cisternae et tunc in conspectu disculcetur. Post filtrationem, aquam lavare potest lavare residuam filtrom. Post lavandum, aliquando aer compressus et reliquum liquidum lavandum auferat. Postquam, pulsera filtro aperta est ut residuam filtrom auferat, purga filtrom vestem, pulsere plateas et cistas, et sequentem circulum opus incipiat.

2. Structure

Filtros de platea et diagramma in principio compositur de platea thrust (platea filtrae fixa), platea pressibile (platea filtrae movabilis), platea filtrae et frama filtrae, trabeo (trabeo ferro flato), medium filtrae (pallio filtrae aut charta filtrae etc.), apparatus pulsere, tanka colligere etc.

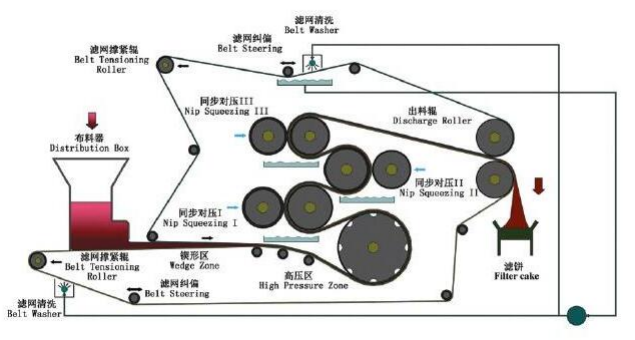

III. Belt Filter Press

1. Structure and Principle

Filtrum cincturae pulseris in principio ex dispositivo driving, drum transmission is, cinerem conveyor, cinerem conveyor, cinerem caliginis superior idler roller, minimum idler roller, ramma, mundator, tensionis apparatus, deflection drum, instrumentum guiding chute, apparatum tensionis pessimum, et dispositivum electricalis, etc. The conveyor belt forms a closed loop by passing around the transmission drum and the tail deflection drum. The idler rollers bear the conveyor lumbar and the materials transferred on it. The tensioning device provides sufficient tension for the conveyor belt to ensure frictional force between it and the transmission drum, preventing the conveyor belt from slipping. During operation, the reduction motor drives the transmission drum, which in turn drives the conveyor belt to run by means of friction. Materiales intrant per cibarium et movent pariter cum cingulo conveyorum, viantes distantiam antequam attirent portum discargationis et postea intraverunt sequentem gradum.

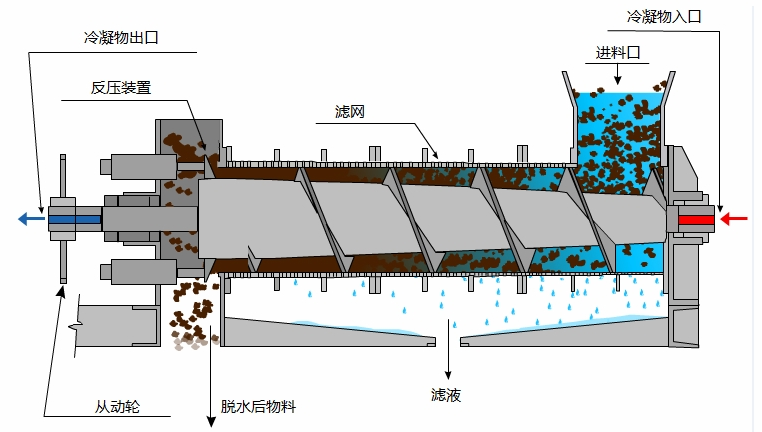

4. Centrifugal Dehydrator

1. Principle

Machina dewateringa centrifugal inter phases solidis et liquidis densitatem utilizat et sub actione fortitudinis centrifugalis velocitatem sedimentationis particiorum solidorum ad separationem liquidi solidi accipiendum acceleratur. The specific separation process is that the sludge and the flocculant solution are sent into the mixing room of the drum through the inlet pipe. Hic faciunt flocculationem mixtum (si flocculantem additur ante pumpam lacus aut per pipeliniam post pumpam, reactio iam praecepit). Pro rotacio rotor is velocitatis (screw and drum) et resistentia frictionalis in rotore accelerata est et facit layer cylindrica liquidae anulis (zona anulis liquidae). Under the action of centrifugal force, the heavier solid particles settle on the inner wall of the drum to form a sludge layer (solid ring layer). Then, using the relative speed difference between the screw and the drum, the solid phase is pushed towards the cone end of the drum, and after the liquid surface is discharged (shore zone or called the dry zone), the sludge dries and is dehydrated, and is pushed out through the discharge port to be discharged. liquida clara discargetur ab magno fini druma ut possit separationem solidum liquidum.

2. Structure

V. Comparison of Several Sludge Dewatering Machines

Produced onFirmwareCapabilities"), String.Join (", | open recent file | Method | Adventura | Disadvantage |

| 1" (msgctxt: "panel:showusername") to "1 | Machina cum cinere filtrata | Continuous dehydration Compression Mechanical | Facilitate machinae facile est, cum paucis instrumentis ancillaris et paucis consummatio energiae; Ut semper operare potest, conveniens est administrare, et habet magnam dehydrationem capacitatem. | Preces polymerorum alta est, costa operationis cara est, et dehydration is effectivitatem inferior est quam calamorum et calamorum filterum. |

2 | Plate and frame filter press | Intermittent dehydration Hydraulic filtration | Libum filtrom habet altum contentum solidum, altum tempus restaurationis solidi, et minimum consummationem pharmaceuticalorum. | Intermittent operation, with low filtering capacity, and large investment in infrastructure equipment |

3 | Centrifugal sludge dewatering machine | Continuous dehydration The effect of centrifugal force | Infrastructura investigatio minima est, et terra occupatio parva est. The equipment structure is compact; Nihil aut parvulus agentes chemicales additi sunt; The treatment capacity is large and the effect is good; The total treatment cost is low and the automation level is high; The operation is simple and hygienic. | Currente, in Sinis, centrifuges importantur in maiorem, quæ cari sunt et multa electrica consumnt. Tenit pignus harenam et calamum, qui facile potest auferre vasa et producere vocem. |

paper size | Carnem de dewateringa calicio fixatum | The effect of centrifugal force Continuous dehydration | Parvus in magnitudine, spatio solis salvat; Low power consumption, equipped with an automatic flushing device, the equipment will not be clogged, the efficiency is highly automated, and it can operate continuously without human intervention for 24 hours. | Quantitate pigri discargentis relativamente parva est, et contignatio humilitatis maior est quam illud lapidis et lapidis. It is suitable for use in places where there are no strict requirements for moisture content. |

Si volueritis ad produktos nostros aut habere quaestiones, implete formam inferiorem, quaeso. We will contact you immediately after receiving it. Thank you for your choice.