Polyacrylamide (PAM) is a water-soluble linear polymer and is the most critical and widely used flocculant and settling agent in mineral processing wastewater treatment, often regarded as an indispensable "universal aid." Correct selection is paramount, as it directly determines treatment efficiency, operational costs, and the performance of downstream processes.

I. Role and Effectiveness of PAM in Mineral Processing Wastewater

Mineral processing wastewater is typically characterized by: large volume, high suspended solids (SS) content, presence of heavy metal ions and residual reagents, complex composition, and variable pH. PAM primarily performs the following functions to achieve water reuse or compliance discharge standards:

Flocculation and Sedimentation:

Mechanism: Active groups on the PAM molecular chain function through charge neutralization and bridging sweep flocculation. They adsorb onto fine suspended particles and mineral fines, forming large, dense flocs ("pin flakes"), drastically accelerating their settling rate.

Effect: Significantly improves the efficiency of thickeners and clarifiers, producing clear supernatant and markedly reducing suspended solids content. This is its core function.

Slurry Thickening:

Mechanism: In thickeners, PAM promotes the aggregation of fine particles, releasing water trapped between them to form a denser underflow.

Effect: Increases the rate of water recovery and reuse, reduces fresh water consumption, and facilitates tailings disposal (e.g., dry stacking).

Filtration Aid:

Mechanism: The formed flocs are large and robust, resisting breakage. During filtration, they create a porous filter cake, reducing cake moisture content and increasing filtration rate.

Effect: Enhances the efficiency of filters (e.g., filter presses, belt filters), reducing energy consumption and cycle times.

Removal of Heavy Metals and Contaminants:

Mechanism: Through adsorption and co-precipitation, PAM can help remove heavy metal ions (present as hydroxides or complexes) by entrapping them within the floc structure.

Overall Effectiveness: Using the appropriate PAM can typically reduce wastewater suspended solids from thousands of mg/L to below 150 mg/L (for discharge), and even to below 30 mg/L (for reuse). Clarification rates can be improved by several-fold to tens of times.

II. The Key to Success: Correct Selection

There is no "universal" PAM. Selection must be site-specific and wastewater-specific. Laboratory testing is mandatory.

1. Understanding PAM Types

Classified by ionic charge, PAM has four main types:

Cationic Polyacrylamide (CPAM): Best for organic-rich, negatively charged colloids. Less common for primary sedimentation in mineral processing; more frequently used for subsequent sludge dewatering.

Anionic Polyacrylamide (APAM): The most commonly used type in mineral processing. Ideal for neutral or alkaline water to flocculate positively charged inorganic particles (e.g., metal oxides, silicate slimes).

Non-Ionic Polyacrylamide (NPAM): Suitable for acidic or neutral conditions where particle surface charge is weak. Less affected by pH in saline environments but has slower dissolution.

Amphoteric Polyacrylamide (AMPAM): Used for highly complex, variable pH wastewater. More expensive and less common in mineral processing.

2. Core Selection Procedure

Step 1: Water Quality Analysis (The Foundation)

pH Value: The primary guide for ionic type.

pH < 7 (Acidic): Prioritize Non-Ionic (NPAM) or Cationic (CPAM).

pH 7-14 (Neutral-Alkaline): Anionic (APAM) is usually the best choice.

Suspended Solids (SS) Concentration & Composition: The mineralogy (iron, copper, phosphate, lead-zinc ore) dictates particle surface charge.

Zeta Potential: Measures the surface charge of particles. A highly negative potential requires a high-charge-density CPAM for neutralization; a positive potential requires APAM. This is one of the most scientific selection criteria.

Residual Reagents: Collectors, depressants, etc., can alter particle surface properties, affecting PAM performance.

Step 2: Laboratory Jar Testing (MANDATORY)

This is essential for screening the optimal product and dosage.

Sample Preparation: Collect representative wastewater samples.

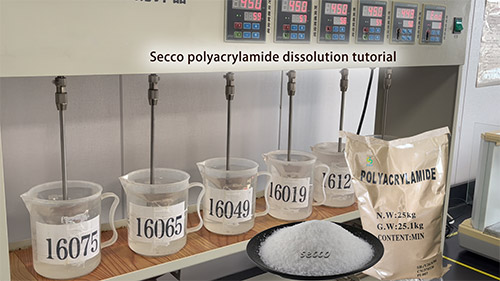

Solution Preparation: Prepare 0.1% solutions of different PAM products (freshly prepared, use within 24-48 hours).

Stirring Test:

Add a measured dose of PAM solution under rapid stirring (200-300 rpm) for 1-2 minutes for initial mixing.

Reduce to slow stirring (50-60 rpm) for 5-10 minutes to observe floc formation (size, density, and rate).

Settling Observation: Stop stirring. Observe settling speed, clarity of the supernatant, and compactness of the sediment.

Evaluation: Measure turbidity or SS of the supernatant. Compare the effectiveness of different types and dosages. The goal is to find the product that achieves the desired clarity at the lowest dosage.

Step 3: Pilot-Scale Testing

After successful jar tests, conduct on-site pilot trials to simulate real conditions (flow rates, mixing energy) to confirm results and fine-tune operational parameters.

3. General Selection Guide (Reference Table)

Ore Type Typical Wastewater Characteristics Preferred PAM Type Notes

Iron Ore Neutral-Alkaline, negatively charged particles Medium-High Hydrolysis Anionic (APAM) Most common, fast settling, large flocs

Copper/Lead-Zinc Ore Often acidic, contains sulfur & heavy metals Non-Ionic (NPAM) or Low Hydrolysis Anionic (APAM) Depends on specific pH and Zeta Potential

Gold Ore (Cyanidation) Alkaline, contains cyanides Anionic (APAM)

Phosphate Rock Acidic Non-Ionic (NPAM)

Coal/Coal Washery Neutral, contains coal fines Medium-Low Hydrolysis Anionic (APAM) Non-Ionic sometimes used

Sludge Dewatering Thickened underflow from clarifiers Medium-High Cationic (CPAM) Used for filter presses/centrifuges

Note: This table is a general guideline only. Laboratory testing is essential.

III. Key Application Considerations

Dissolution and Preparation: PAM must be fully dissolved ("aged") to activate. Use dedicated mixing tanks and follow the "** sprinkle slowly into the vortex**" rule to avoid clumps ("fish eyes"). Agitation should be sufficient for mixing but not so violent as to cause shear degradation of the polymer chains.

Dosage: More is not better. Overdosing can cause restabilization of colloids, making the water cloudy again, reducing efficiency, and increasing costs. The optimal dosage, typically between 1-10 ppm (g/ton of water), is determined by jar testing.

Molecular Weight: Higher molecular weight provides stronger bridging and larger flocs but dissolves slower and is more susceptible to shear degradation. Medium to high molecular weight (12-18 million) PAM is commonly used.

On-Site Adjustment: Water quality can fluctuate. Continuous monitoring and slight adjustments to the dosage point and amount may be necessary.

Summary

Effectiveness: PAM is highly effective and is the core technology for efficient sedimentation, water reuse, and compliance in mineral processing.

Selection: Is a systematic, scientific process. "Test first" is the golden rule.

Analyze water quality (especially pH and Zeta Potential).

Screen ionic type and specific products via jar testing.

Conduct pilot trials to finalize parameters.

Key to Success: Collaborate with technically capable suppliers who can provide a range of samples and technical support to conduct these tests, ensuring you achieve optimal treatment results at the lowest possible cost.

If you are interested in our products or have any questions, please fill in the form below. We will contact you immediately after receiving it. Thank you for your choice